Plastic Roll Banners – Registration Shift

Printing Plastic Roll Banners – What is Registration Shift?

Plastic roll banners and plastic bags are printed using flexography and this is a totally different animal than offset lithography.

In offset lithography, the process with which most graphic designers are familiar, the ink is on the same level as the areas of the plate that do not hold ink.

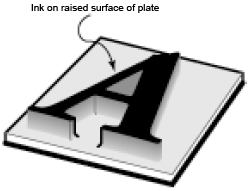

In contrast, flexography (or flexo) – so named for its flexible printing plates – is a letterpress printing process similar to the old-style block printing. To be more accurate, it’s like printing with a big rubber stamp. The ink is applied to the raised surfaces of a rubber printing plate and pressed onto the poly surface to transfer the image.

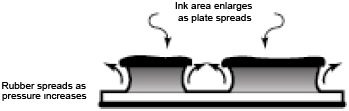

Flexo printing tends to spread more because the surface of the rubber plate is slightly compressed as it applies ink to the poly.

Precision of a flexo presses are usually not as fine as an offset press, and multi-color registration tends to shift much more. Shift can be as much as 1/8″.