How We Handle Full Bleeds In Roll Banners

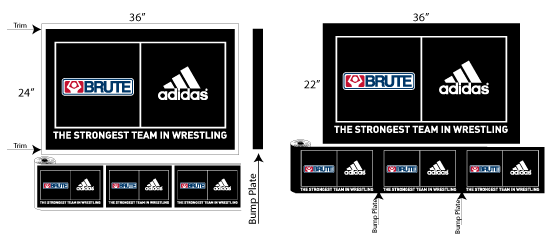

At Northcoast Banners, we print full bleeds on a case-by-case basis. When you submit your artwork, we will trim the outer edges of roll banners by allowing for at least 1” of margin space to ensure a safe and accurate trim that will elegantly complete your banner.

It is important to note that flexo presses to do not allow for continuous print. Now, because of the way that plates mount on the cylinder, a gap occurs between the lead and trail edges as they butt together, creating a ‘plate gap.’

Therefore, you should integrate the plate gap in your roll banner instances to compensate for this issue. Using a solid color BUMP plate that is wider than the normal gap fill, the BUMP plate will butt up to the primary design elements and eliminate the appearance of any plate gap fills, making the seam appear as close to invisible as possible.

If your roll banner art involves colors other than white between the images, select a PMS color that will blend well into the background. Also, using our 5th or 6th printing deck, a spot color can be printed to fill the plate gap.

Our experience has indicated that black is the safest color fill in plate gaps. Although we have successfully created full bleed roll banners with bump plates that were not black, black is by far the safest choice of colors for your bump plate.